Why should the chicken manure of the organic fertilizer production line be fermented?

Chicken manure contains a large amount of intestinal flora, which cannot be directly applied. Therefore, it must be fermented at high temperature. The main purpose of fermentation is to kill microbes and increase the organic matter content.

Fermentation is mainly carried out in the fermentation groove. It is better to add the fermentation bacteria at the same time, and then cover it with agricultural mulch. The fermentation is usually 10-20 days.

The chicken manure after fermentation is roasted and crushed. The pulverized chicken manure can be applied directly, but it is only called traditional farm manure, and it is not yet commercial organic fertilizer.

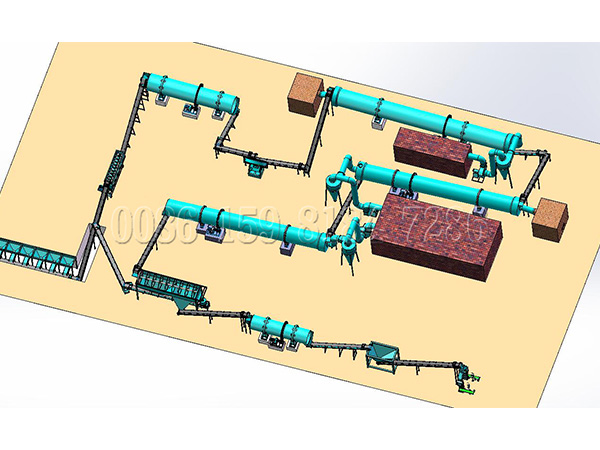

In terms of appearance, commercial organic fertilizers are divided into two types: powder and granules. If you want to produce granular commercial organic fertilizers, you also need granulation process. The granulation production equipment of organic fertilizers generally uses disc granulator. The granular fertilizer production line mainly includes crushing equipment, mixing equipment, granulation equipment, drying equipment,cooling equipment, screening equipment and packing equipment. Welcome to contact us for details.